Novasom’s Validation systems – Fault Injection HIL ®

Our unique and patented Fault injeciton Validation System has been minded thinking to the limitation of systems availiable on nowadays market, with the vision of an experience born and grew up in the past 25 years of activity for T1 ADAS and OEM’s, struggling with ISO 26262A tests.

The system is composed by a nail bed , specified on the DUT and an array of embedded CPU that drive the injections on each nail to allow system react.

Why we’ve done this ? Because It’s clear that complex safety critical products require tools and methods to be validated in every possible test cases also at white box level, and we’re not discoursing here about the necessity of a complete and complex Software In the loop SIL approach that’s absolutely needed , but that the fault shall be really injected with proper in time and value, so real, not only simulated with any FMDEA table or a SW trap.

This practical approach gives you the total vision : all the possible fault has been really tested and the DUT system is able to handle it properly. Plus you have the proof .

How it works ?

A nail bed that touch test pad of your products , properly minded on a DFT analisys, connected to an array of embedded CPU ( no os there, things are deterministic ) able to – properly – inject fault you can determine with any vector or matlab tools , in order to give you the possibility to test your HW and SW response to that from your SIL enviromental or tools.

In everyone of the thousands and thousands cases, pin , injection needed . Yes.

While doing validation of safety critical systems in the automotive , railways and military market , it’s clear that the validation became complex when numbers of test points-cases goes high to several hundreds-thousands: not feasible by any operators by hands.

Unfortulately , the big thick Software In the loop emulations systems , that could offer also an hardware connections board , are not deterministic at microseconds ( sometimes much much over) , cost a lot of time and money in licences, hardware and learning curve .

Sometimes , they create also significant problems when to create and inject hundreds or thousands levels of contacts withimpedence matching level , distorcing signals or alterating the working status of delicate circuitery. WHere and how to touch a pcb is not an options and need to be studied with a proper DTF.

Our engineering pragmatic approach have clearly seen those limitation on the field , and the necessity drove us to develop a system able to be used by those extremely wide and complex SW validation SIL platform tools – we absolutely need as main source of test cases – SW analisys.

This is why and how our Fault Injection HIL’s was born.

Testing and validationg your specific products with pure Hardware-in-the-Loop (HIL) Fault injection systems you can simpy drive with 232 message, already integrated or simply integratable in your Functional safety analysis or SIL tools , both at HW ans SW level and to make real test in every possible scenario.

Send the command, get the results in milliseconds, with precision in the microsecond range and time determinism — as only a real embedded system can deliver.

Use it integrated into any validation system — SIL you are using — it will work perfectly because it is message-based.

A high-level graphical proprietary programming language, which is widely used in today’s testing world using FPGAs, cannot provide such capabilities.

This new holistic approach, which combines system-level and product-level fault injection, will allow you to validate, test, and report any HW fault behavior as well as any related SW diagnostics or processes, in ways that haven’t been possible before.

Our HIL systems are standard products, but they can be adapted by our engineers to meet any of your specific needs — with their own dedicated nail bed fixture — just like with electrical I/O fault injections. This addresses, for example, the requirements of ISO 26262, EN 50155, and MIL-STD-461E, while providing you with real, replicable reports.

A real-world, full validation and testing capability is available now , for both HW ans SW side. The academic methodology we studied for years states theoretical fault models, which are sometimes simply not real and not enough to justify what has been done or tested.

Any Hardware test is now really possible, enabling you to test the actual global functioning of your system as disturbed in any way the FMEDA analysis (now truly meaningful!) or test cases suggest.

With our help — for sure — because our team will work with you to ensure the success of your testing plan.

Using these systems, you will benefit from our engineering expertise — included in the package.

Through custom extension boards supporting CAN, Ethernet, I2C, and SPI, our systems will provide comprehensive, flexible testing. Many clients already benefit from the speed and depth our systems deliver in functional safety analysis. Join us!

Seems bold, but we did it

and have been doing it for our clients for over 20 years

To give absolute reiliability to our fault injection system we’ve developed an architecture based on a backplane, a main CPU board that reads commands from a high-level C/C++ system , that shall drive the fmdea minded test, along with pure embedded I/O boards that are fully expandable and durable. This setup integrates seamlessly into a rugged mechanically defined nail bed for specific hardware-in-the-loop (HIL) testing needs.

Our custom HIL systems are complex and robustly built, but they’re invaluable.

A fan-less , embedded architecture that will never fail a measure and will never need a reboot also working 27/7 . And it is lifetime warranty , call us and discover how

You’ll save time, effort, and cost by detecting and resolving hidden issues early, testing everything in every real condition at the HW ans SW level.

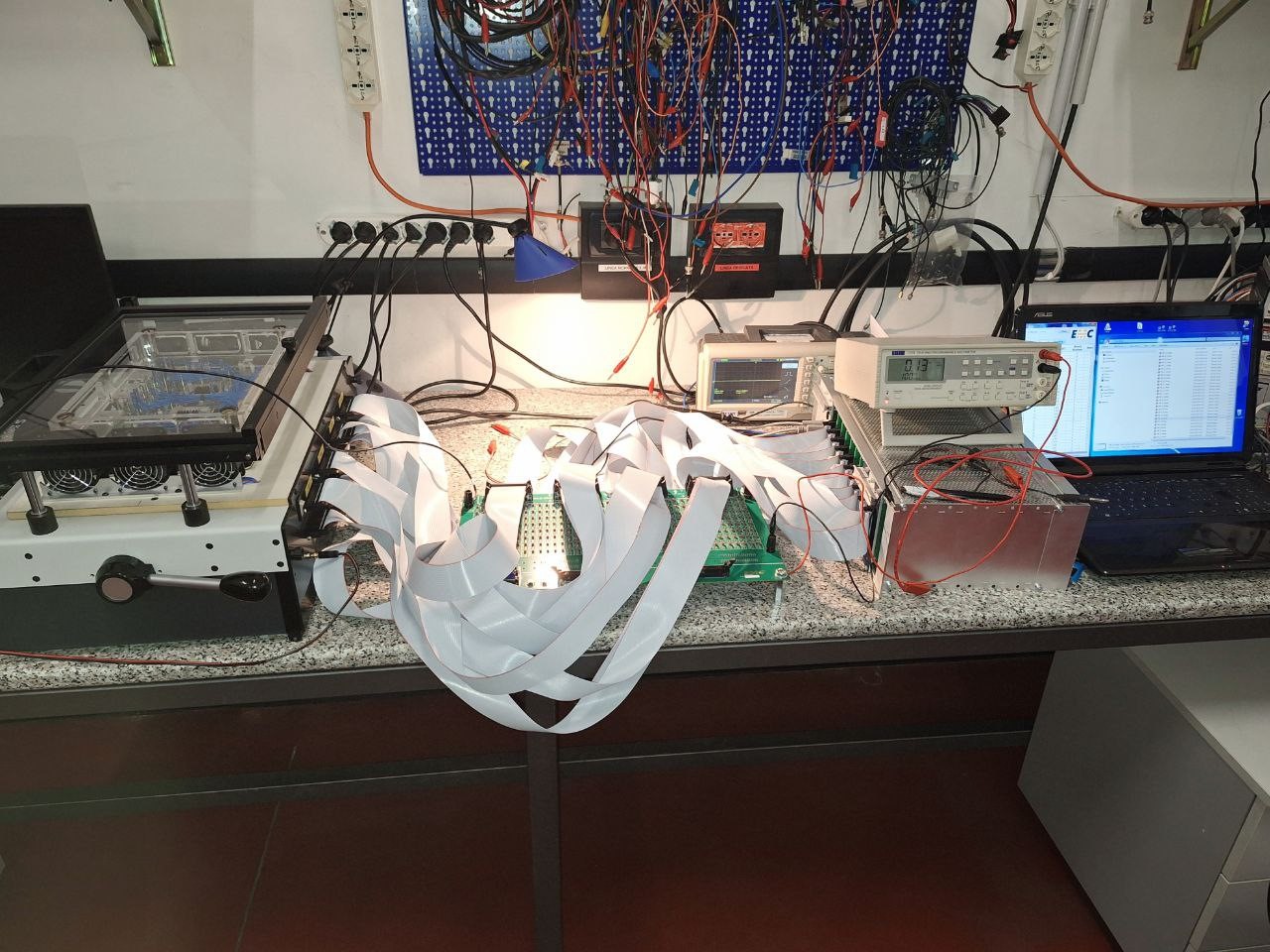

We know this might not look like a polished marketing photo, our CEO ask us to do in this way, because it’s real—from our labs. The large green connector board at the center allows engineers to monitor every signal in the hardware-in-the-loop (HIL) system, offering comprehensive insight for troubleshooting complex setups.

Our Fault injection HIL system is intricate, and while not all details can be shown here, we’re ready to discuss how it can resolve your specific needs. Call us—we’re here to help!

Real-time measurement results

We’ve taken a crucial step forward, moving from statistical-theoretical analysis to real-world security measurements. Our Hardware-in-the-Loop (HIL) system provides real-time measurement results as your system operates, enabling your development team to identify faults and enhance resilience.

Yes, it’s feasible with our HIL system.

100% customized to your requirements

Our Hardware-in-the-Loop (HIL) system is designed to meet your exact needs, based on a COATS object. Built on years of testing experience, it can inject fault signals to reveal how complex products may fail, tracing failures and improving reliability at the design level. This is functional safety analysis made real—without requiring years of development time or added costs.

Validate your project in all the scenarios and failure modes

When is custom hardware development the right choice? Not all systems interact seamlessly, and in a business relying on reliable operation, this can cause issues. Our Hardware-in-the-Loop (HIL) system is tailored to meet the specific circuit needs of your system, adapting precisely to your requirements—never the opposite.

Made to measure

This isn’t a statistical method or new software; it’s a real hardware system that introduces faults directly at the component level. Our system can simulate issues like a resistor short or capacitor drift, providing practical, real-world electronics testing. Designed by engineers, for engineers, it delivers true-to-life diagnostics for robust product development.

This isn’t a myth—no surprises, no conditions. Everything is guaranteed, backed by our technical support. With Novasom products, you get more than a Hardware-in-the-Loop (HIL) system; you receive a complete, tested solution for your projects. We’re here to support you through all development phases. Just ask!